Total Freeze Ice Tank

Possesses the largest (17000RT-HR) and most ice-storage air-conditioning engineering records in Taiwan.

Cryogenic Freezer

Completed the largest (500 ping, 12 meters high) single warehouse -25 ℃ low temperature freezer in Taiwan.

Limit 0.1℃ Per Meter

Completed the constant temperature and humidity air-conditioning project with a temperature limit of 0.1°C per meter in the ultra-precision three-dimensional measurement room.

1% Ultra-low Humidity

Completed the production line air-conditioning project with 1% ultra-low humidity.

Super Clean Room

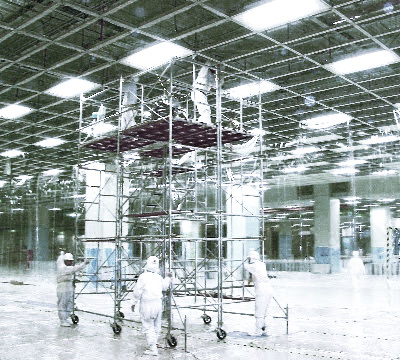

Completed the 1100m² CLASS 1 super CleanRoom project.

CR Engineering

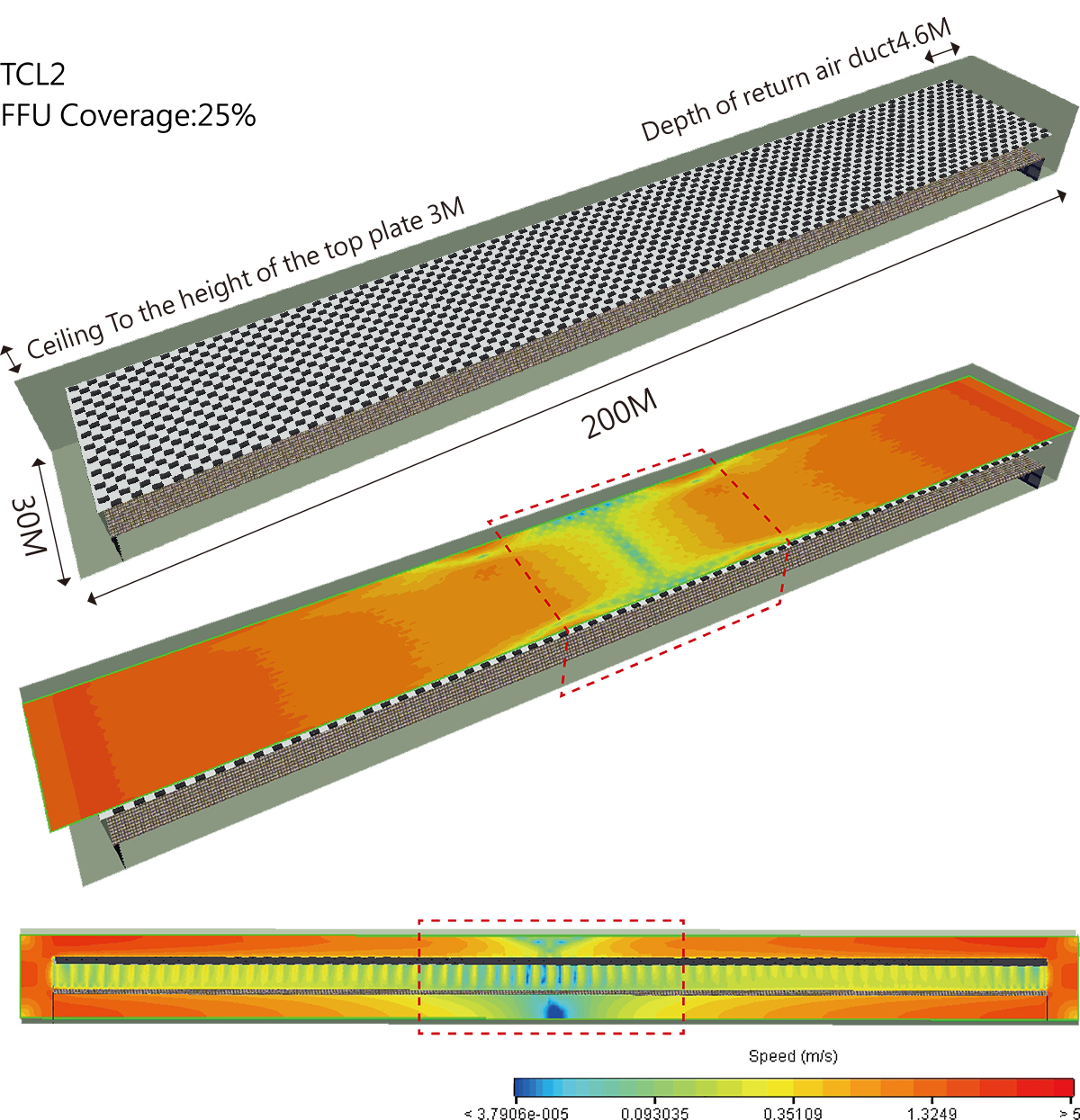

Complete the CRI project of CEILING GRID-FFU SYSTEM with a single case area of 70000m² (CLASS 100~1000)

Factory Air Conditioning Project

Completed a single case of 12,000 tons of plant air conditioning projects.

Air Conditioners For Super High-rise Buildings

In 1991, the air-conditioning project of the first 26-storey super high-rise building was completed.

Special Refrigeration Engineering

Completion of special refrigeration engineering for cooling and liquefaction of CO² at -40°C.

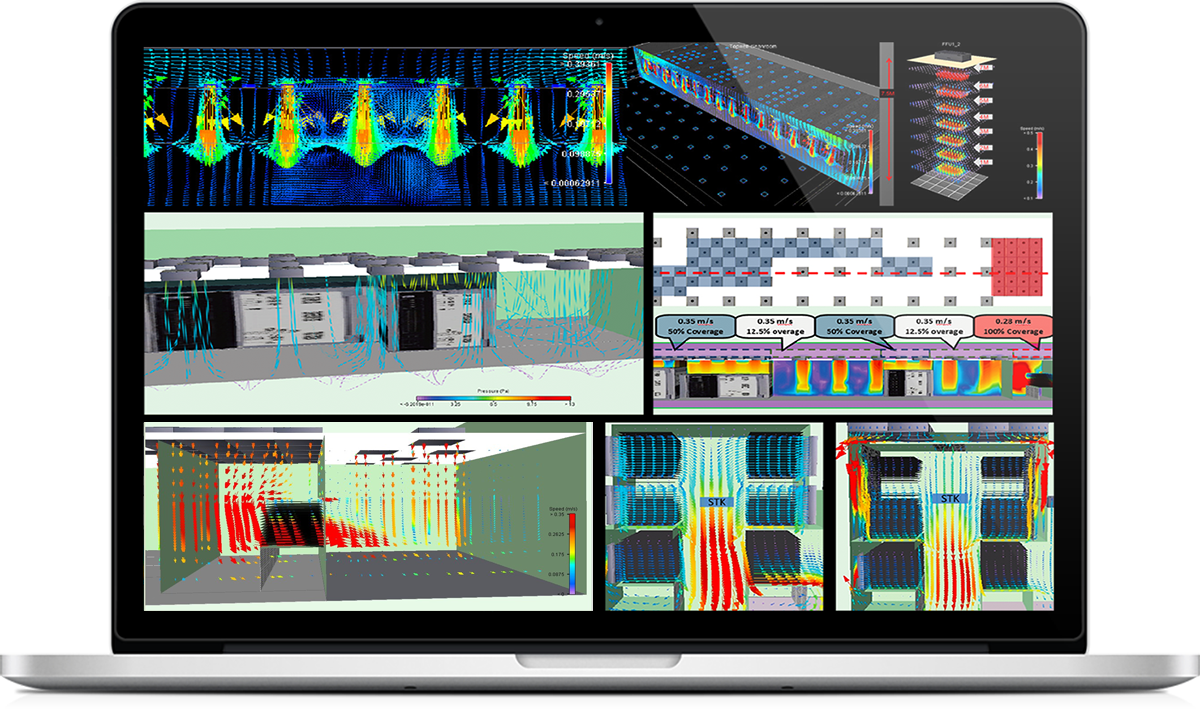

Particle Dispersion And Air Flow Simulation

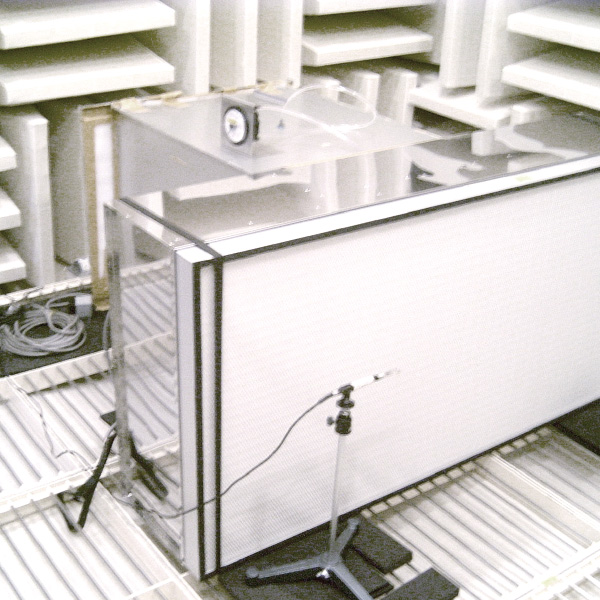

The particle contaminant in the cleanroom is mainly generated by process equipment,transportation equipment and operator.In order to control the contaminant,the air flow cleanness must be maintained. By utilization of ultrasonic 3D anemometer,particle counter and 3D air flow simulation program,we are able to predict the air flow and particle dispersion pattern so as to assist the cleanroom design.

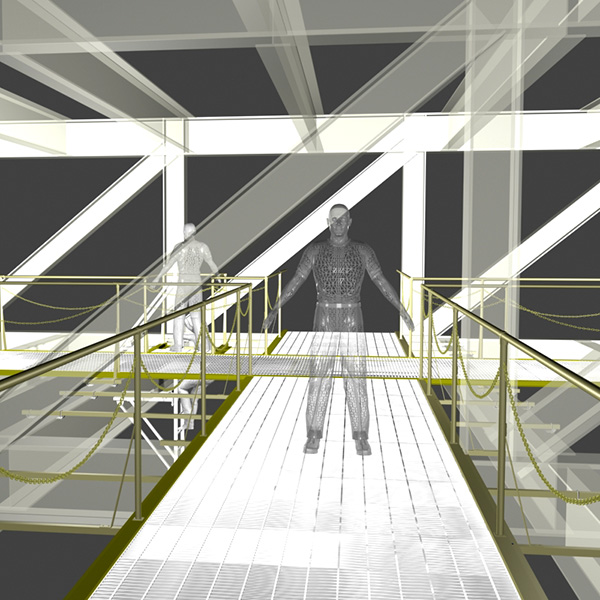

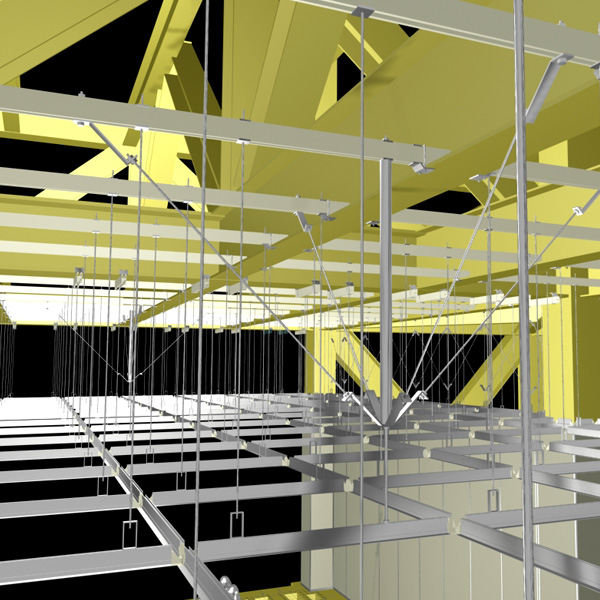

3D Structure Stress Analysis For Cleanroom Interior Material

To ensure the quality of cleanroom construction,we have developed the cleanroom related products including ceiling grid,tool partition,DCC and MAU. As the products are manufactured in our factory,we are able to control the quality throughout the process stages of design, production,transportation and storage. Especially in design stage,with simulation programs to facilitate the analysis of assembly and structure stress,and to be tested by our factory equipped 3D production system (FDM 200MC&PRODIGY PLUS) and Micro-Computer Universal Testing Machine,we are able to assure the function and safety. In addition,Topwell is also work with the institute to develop the interior design software by incorporating the Topwell material and years of empirical data,so as to provide the industry with a systematic cleanroom interior design and application standard.

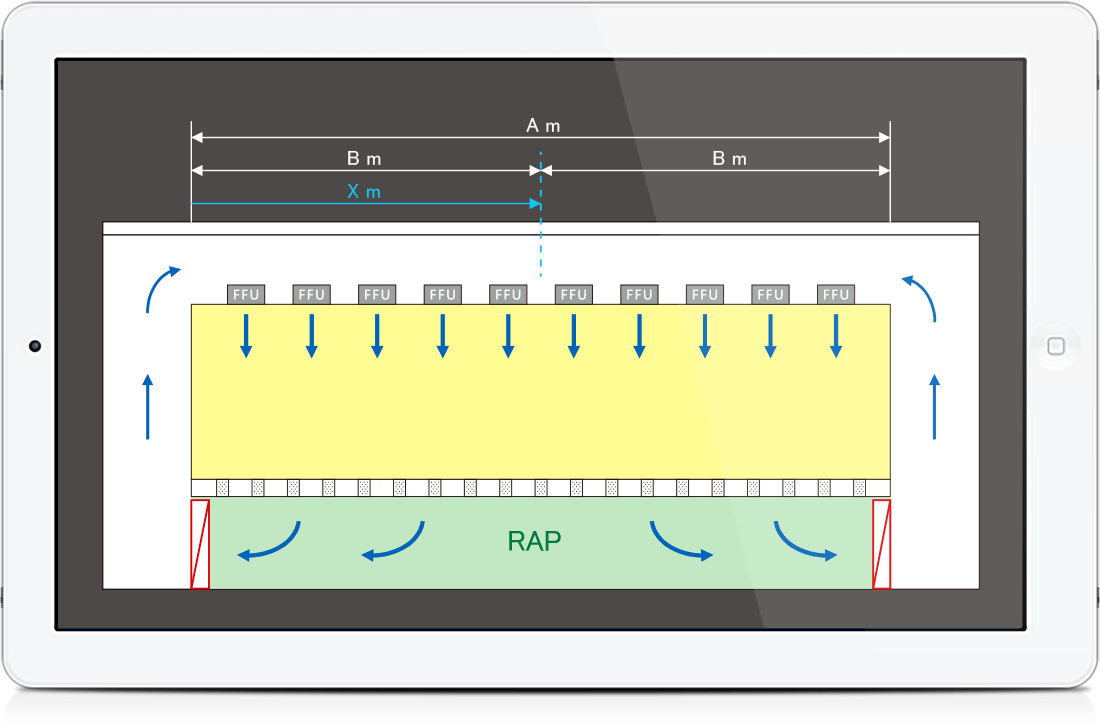

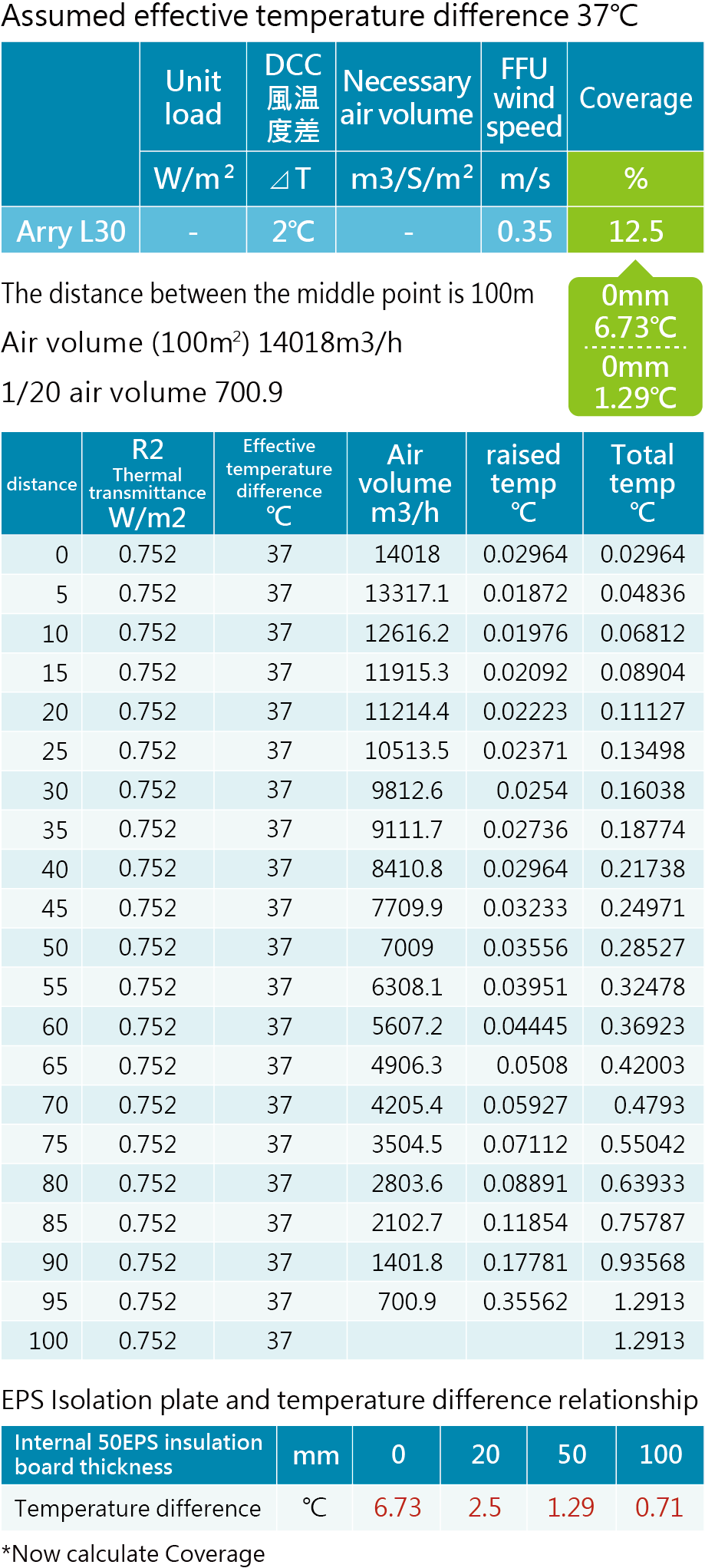

Airflow And Temperature Rise - Case Study

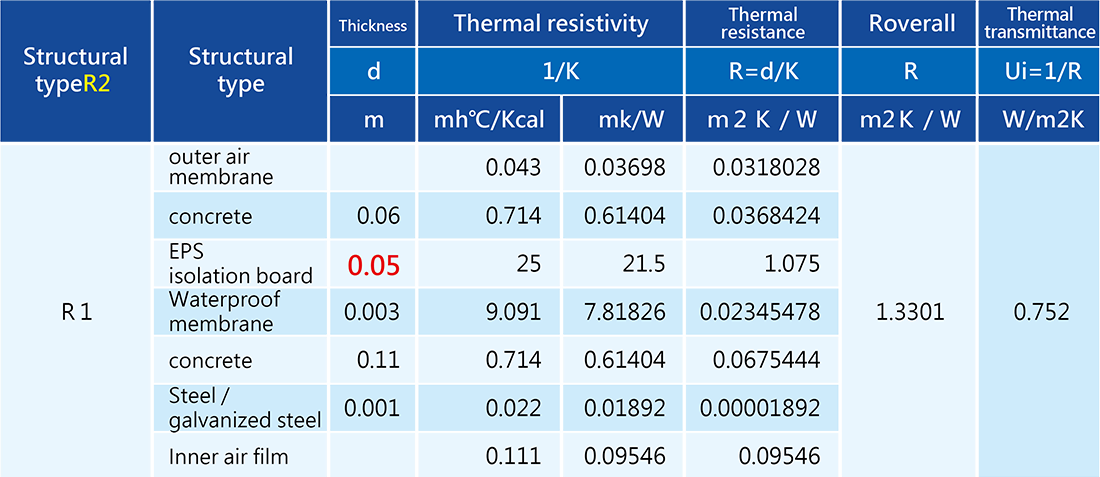

Thermal Resistance Analysis Of Plant Structure

Roof heat load deference tempreture calculation (Calculation at the minimum air volume position Calculation of effective temperature difference.)

1.Calculation of thermal transmittance (calculated when the EP insulation board is 50mm)